We Specilizing

Ferro Silicon Nitride

Silicon Nitride

Manganese Nitride

Vanadium Nitride

Ferro Chromium Nitride

Ferro Vanadium Nitride

Silicon Manganese Nitride

Ferro Manganese Nitride

Calcium Metal

Magnesium Igot

Processed Magnesium Product

Manganese Metal

Silicon Metal

Cored Wire

Calcium Silicon Barium

Ferro Silicon Magnesium

Ferro Silicon

Ferro Silicon Zirconium

MSDS DATA of Product

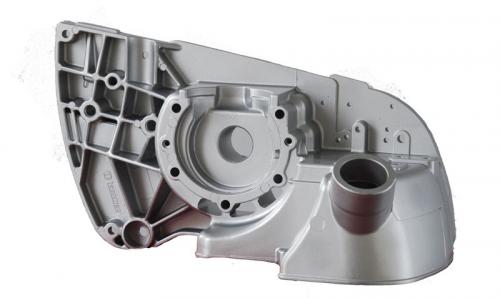

Processed Magnesium Product

Processed Magnesium Product Properties

Processed Magnesium product is made of Magnesium and Magnesium alloys. Magnesium alloys is the lightest metal alloy structural material, the proportion is only 1.8, respectively,queaul 1/3 of aluminum and 1/4 of iron. Its specific strength is up to 133, can be comparable with specific strength of titanium, that make magnesium alloy can be used as high-strength material. Moreover,Magnesium alloys as a structural material, it is a small specific gravity, high specific strength and stiffness, good electrical conductivity and thermal conductivity, excellent electromagnetic shielding properties, ease of processing and recycling molding, etc.,

Processed Magnesium Product Application

Processed Magnesium products are divided into die cast magnesium alloy and extruded magnesium alloys. They are very different both in composition, microstructure and properties. Die Cast magnesium alloy is mainly used in automotive parts, mechanical shrouds and electrical components; extruded magnesium alloys are mainly used in sheet, extrusions and forgings. Die Cast magnesium alloy are broader application than extruded magnesium alloy.

Extruded Magnesium Profile Specification as Magnesium Alloys

BRAND |

SPECIFICATION% |

|||||||

Mg |

Al |

Mn |

Zn |

Si |

Cu (max) |

Ni (max) |

Fe (max) |

|

| AM50A | Balance | 4.5-5.3 | 0.28-0.50 | 0.20max | 0.05max | 0.008 | 0.001 | 0.004 |

| AM60B | Balance | 5.6-6.4 | 0.26-0.50 | 0.20max | 0.05max | 0.008 | 0.001 | 0.004 |

| ZA91D | Balance | 8.5-9.5 | 0.17-0.40 | 0.45-0.9 | 0.05max | 0.025 | 0.001 | 0.004 |

| AZ63B | Balance | 5.3-6.7 | 0.15-0.7 | 2.5-3.5 | 0.10max | 0.02 | 0.002 | 0.003 |

| AZ80A | Balance | 7.8-9.2 | 0.12-0.50 | 0.20-0.8 | 0.10max | 0.05 | 0.005 | 0.005 |

| AZ31B | Balance | 2.5-3.5 | 0.20-1.0 | 0.6-1.4 | 0.10max | 0.05 | 0.005 | 0.005 |

Size (mm)

Magnesium pipe, Magnesium bar, pure Magnesium, DC Cast billet, Magnesium alloy, all kinds of profiled Magnesium products.